Overview

HOW

WE MANAGE

CJ CheilJedang is aware of the potential environmental impact of our products and strives to minimize those

impacts across the entire product development process. Can we make bio-degradable ingredients?

How can we reduce packaging? Is there a more efficient way to recycle waste materials? We ceaselessly ask

ourselves these questions, look for solutions and apply them to production to enhance eco-friendliness. Until the

day CJ CheilJedang fully realizes a complete cycle of Nature to Nature, we will keep coming up with new questions.

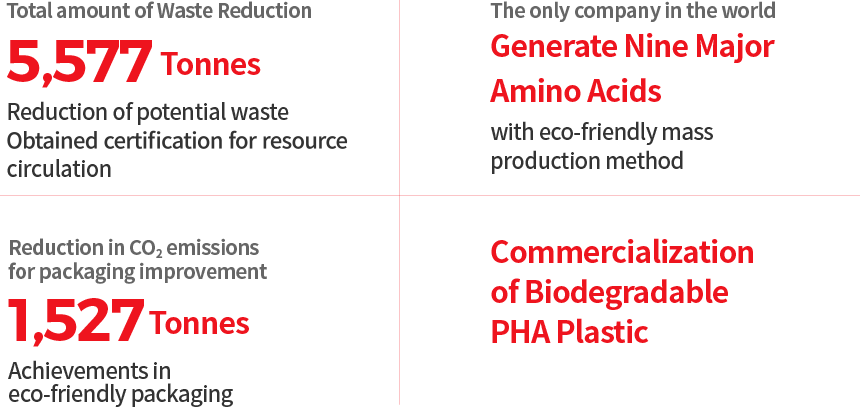

2020 KEY

FACTS &

FIGURES

Implementation of sustainable environmental management

Establishment of a sustainable environment system

Implementation Strategy

CJ CheilJedang is establishing mid- to long-term sustainable environmental goals and strategies to minimize environmental impact. Aiming to be

carbon neutral in 2050, we will gradually implement carbon emission reduction, eco-friendly energy, plastic reduction, waste resource circulation,

and commercialization of biodegradable technology in the procurement-production-sales-recovery process. To accelerate this process, we are

setting up a task force to establish a sustainable environmental management system. This system will serve to minimize environmental impacts

caused by GHG emissions, energy, water usage, and help us organize actions against climate change risks. We will re-establish our environmental

management principles, set mid-to long-term goals, and enact an implementation system to publish a special report within this year.

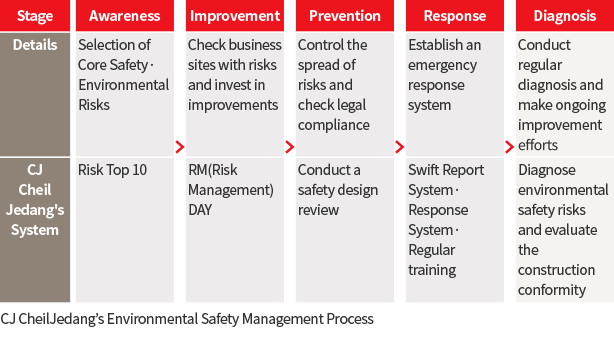

Environmental Safety

Management Process

Under the slogan of “Create an OnlyOne

safety-first culture that puts the safety of

customers and employees first in all business

activities,” we have established a step-by-step

environmental safety strategy. This plan

encompasses environmental safety & risk

awareness, improvement, prevention,

response, and diagnosis. In this way, we can

preemptively identify and address core

environmental issues such as chemical

spillage and malodor.

Waste Reduction Activities

CJ CheilJedang endeavors to minimize waste

generated in its production processes and

increase recycling rates. We are seeking ways

to reduce waste and create new value by

turning waste into resources. In 2020, we

reduced waste by eliminating stickers on

frankfurter packaging, reducing the weight of

ssamjang and bibigo Porridge containers, and

products smaller. In addition, the residual

plant materials (rice bran and broken rice)

and compressed paper waste generated at

Jincheon BC were approved as resource

circulation by the government.

Carbon Footprint Certified Products

We implement carbon labeling on several products to control GHG emissions across all our production processes. In 2020, a total of seven products maintained their certification.

Technology and Production process development

for sustainable environmental

management

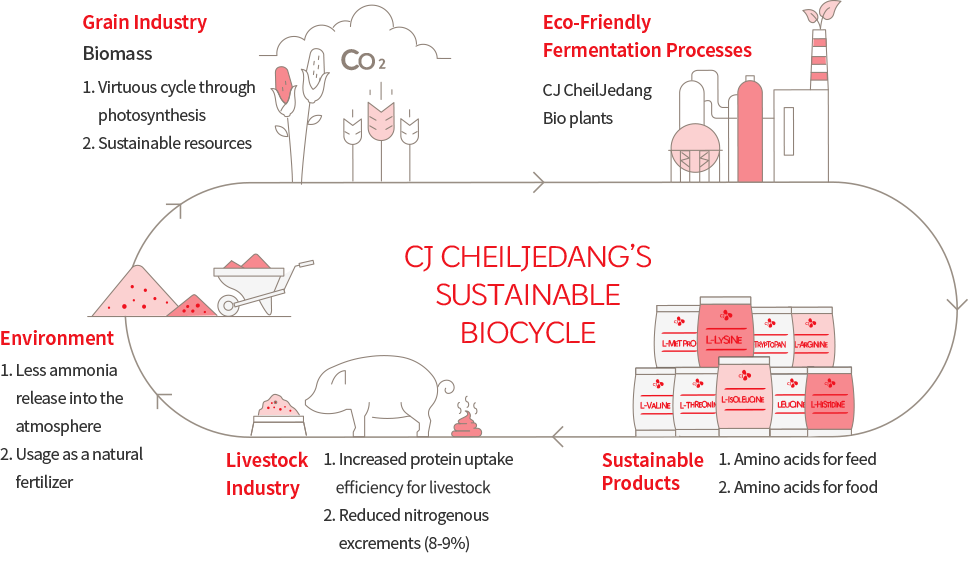

Eco-friendly fermentation processes

CJ CheilJedang produces amino acids through differentiated fermentation processes that use Corynebacterium and raw grains. This eco-friendly

fermentation method significantly reduces the volume of wastewater or gas generated during the amino acids production. In addition byproducts during

fermentation processes can be recycled and reused as fertilizers to boost growth of crop. We also reduced feed consumption and nitrogen generated by

livestock excrement by developing a highly digestible product, thereby realizing greater sustainability.

Production of the nine essential amino acids

With six decades of expertise in microbial fermentation R&D and our state-of-the-art technology, CJ CheilJedang has successfully manufactured

the nine major amino acids using eco-friendly processes. CJ CheilJedang is the only company in the world that produces more than five essential

amino acids in this manner. In 2020, CJ CheilJedang secured the technology to mass-produce Leucine, the ninth essential amino acid we manu-

facture, using eco-friendly process. Amino acids are components of proteins, and livestock intake essential amino acids through feed additives.

CJ CheilJedang will complete a healthy cycle that connects feed (with essential amino acids added) → livestock → food → humans with our

eco-friendly essential amino acid manufacturing processes.

Amino Acids

in Production with

Eco-Friendly

Fermentation

Method

| Key Features | |

|---|---|

| Lysine |

|

| L-Methionine |

|

| Threonine |

|

| Tryptophan |

|

| Valine |

|

| Arginine |

|

| Histidine |

|

| Isoleucine |

|

| Leucine |

|

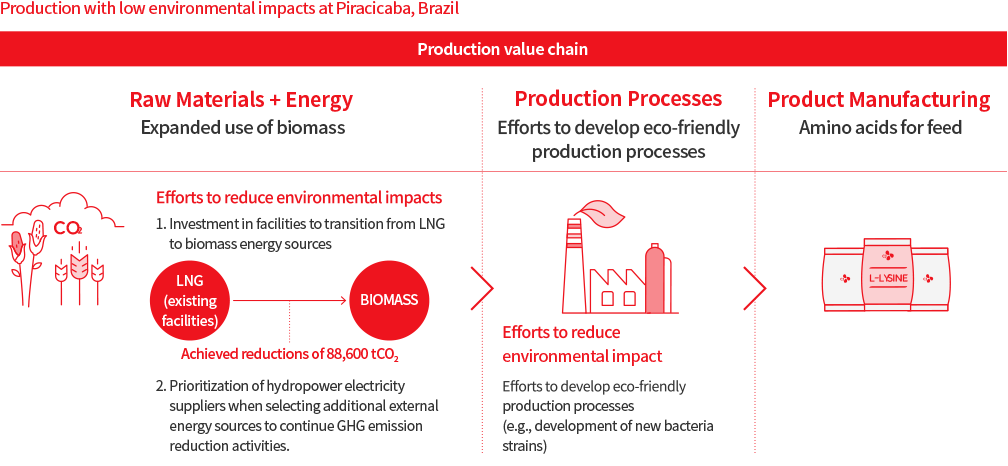

Production with low environmental impacts

Production of eco-friendly lysine at CJ BIO Piracicaba, Brazil

CJ BIO Piracicaba in Brazil, our South American base, produces lysine. In this plant, we produce about 100,000 tons of lysine

a year for swine feed. The CJ Piracicaba business site not only actively carries out eco-friendly production with our green

fermentation method, but also proactively reduces environmental impacts in its production processes. We successfully

reduced CO2 emissions by 88,600 tCO₂ by switching our energy source from LNG to Biomass. Going forward, we will continue

our efforts to reduce our environmental impact.

Expanded use of wood chip fuel and bagasse fuel

CJ CheilJedang switched the production fuel used at its business site in Piracicaba, Brazil, from natural gas to biomass fuels, namely wood chips and bagasse. Wood chips are produced from construction work or come from the unusable roots and branches of trees that have been broken into pieces for easy combustion. Bagasse is made squeezing sugar from sugar cane and grinding sugar cane or cane stalks with leftover residue. Biomass fuels are not only economic but also more eco-friendly since they create fewer GHG emissions such as carbon dioxide, sulfur oxides, nitrogen oxides, etc., than petroleum or LNG.

Efforts to Establish a Sustainable Resource Cycling System

Establishing a sustainable packaging strategy

In step with global environmental trends, which demand reduced packaging waste and care for nature and society, CJ CheilJedang is establishing a resource cycling system. Our sustainable packaging strategies are ‘minimize the plastic’, ‘educate the consumer’, and ‘expand the collaboration’. We reduced plastic use by a total of 1,019 tonnes through technology development, enhanced customer communication and mutual cooperation. Furthermore, CJ CheilJedang is striving to establish a sustainable resource circulation economy by reducing plastic packaging and developing alternative materials.

Enhanced Recyclability of Premium Oil

By using water-soluble adhesives for the containers of Beksul premium oil, we have made waste separation easier for households. We also lightened the weight of lids and PET bottles, eliminated PVC* materials from tech bands, and started using transparent PET to enhance recyclability.* PVC is unrecyclable material that accounts 0.4% of the entire plastic packaging used by CJ CheilJedang

Minimized Use of Plastics in Gift Boxes

We produced the tray for gift set, one of our major products, with 40% of recycled plastic to minimize plastic usage while applying an optimal design. We recycled the residual plastic pieces that remained after the production to minimize plastic use. The all paper design also allows easy separate discharging and increases recyclability. Furthermore, we launched a gift set without any plastic caps for the first time in Korea.

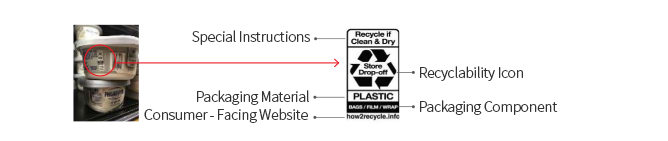

Global How2Recycle label

Our How2Recycle label is a standardized system that informs the public of recycling methods. It is applied to products made by Schwan’s and CJ Food USA.

Education on Domestic Packaging Disposal

From 2022, CJ CheilJedang will develop training content to raise consumer awareness about the correct way to recycle.

Hetbahn container collection·upcycling campaign

As one of our resource cycling activities, we implemented a Hetbahn container collection·upcycling program for our staff. We installed a Hetbahn container collection boxes at worksites, collected containers, and then upcycled them into reflective cards, which were donated to local children’s centers.Efforts to build a circular economic system

We have collaborated with domestic and international value chains and participated in academic conferences and non-profit organizations in order to build a circular economy. In 2020, we participated in Swiss-Korean Innovation Week which was hosted by the Swiss Embassy in South Korea. In the same year, we also joined the ‘SP4CE’ Online Community, an eco-friendly packaging community hosted by SK Global Chemical, and attended the Global Packaging Seminar.Sustainable Packaging Performance

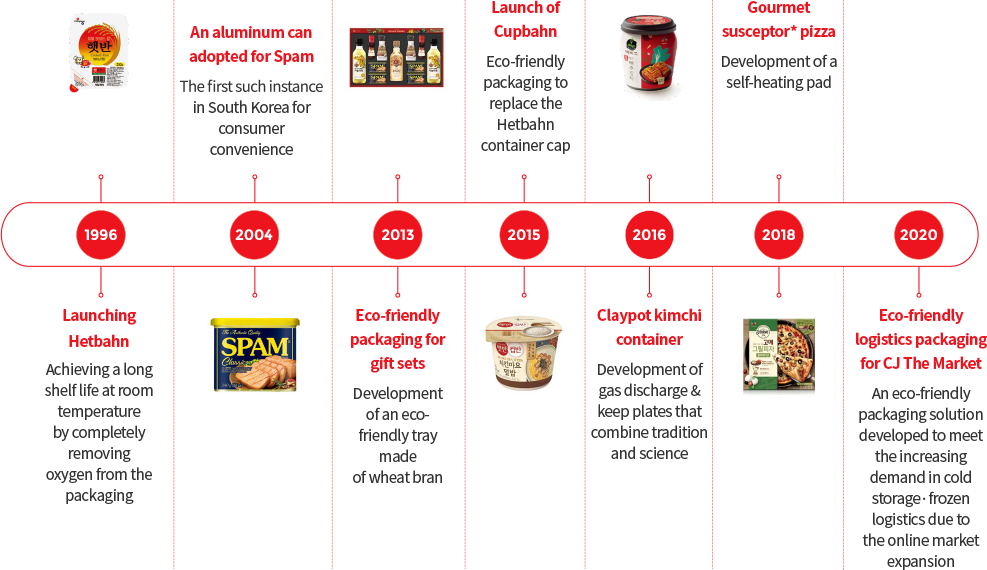

CJ CheilJedang's efforts for eco-friendly packaging

Since our establishment in 1953, CJ CheilJedang has launched the following products as part of its continuous efforts to realize eco-friendly packaging.

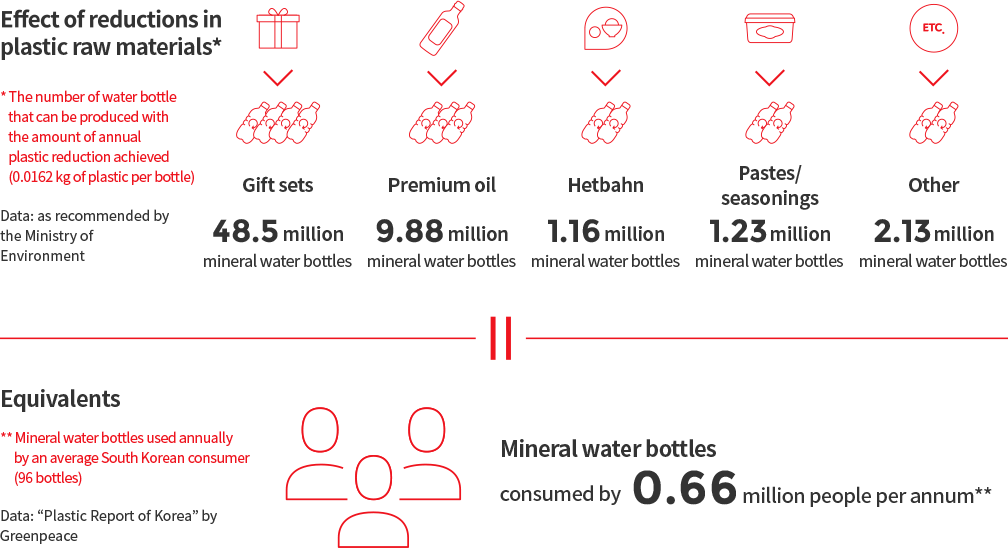

Reductions in plastic raw materials and GHG emissions

Through its sustainable packaging strategy, CJ CheilJedang reduced plastic usage by 1,019 tonnes in 2020. This is equivalent to about 62.9 million 500 ml water bottles. That’s the amount of bottled water consumed by approximately 660,000 Korean people every year.

Commercialization of biodegradable plastics (PHA*)

CJ CheilJedang has successfully developed a biodegradable PHA and commercialized it. This technology is the result of collaboration with three domestic companies. Thanks to our PHA mass-production and packaging development technology, the PLA film production infrastructure of SKC, and the compounding capability of Woosung Chemical to mix and process more than two biodegradable materials, we were able to intro- duce this new product. Going forward, we will gradually replace our disposable packaging materials with biodegradable (PHA) materials.

* PHA is the only bioplastic material that is biodegradable in soil as well as in the ocean. In February 2021, it acquired four types of TUV biodegradability certification, which ishighly-regarded in Europe and North America.

TCFD FRAMEWORK

Humankind is now facing the climate crisis of global warming. It is not a regional crisis but a global climate catastrophe that threatens all of humanity. To this end, the international society is resolved to implement global efforts to address the issue of climate change. The Financial Stability Board (FSB), an international financial organization, established the Task Force on Climate related Financial Disclosure (TCFD) and presented global standards for the effort. CJ CheilJedang seeks to join the trend of the global response to climate change. We will strive to implement the recommendations by TCFD by reducing GHG emissions and increasing the use of renewable energy to enhance national sustainability.

| Status | Plan | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Governance | We have established the Coporate Sustainability Committee, which identifies major issues of sustainability, including climate change and environmental management, and reviews and approves related performances and improvements. Furthermore, the committee organizes the Sustainable Environment Management Council, which is chaired by the CEO, to execute and manage climate change and environmental management-related strategies approved by the Board of Directors. | To realize the virtuous cycle of Nature to Nature, CJ CheilJedang’s Sustainability Purpose in which we obtain resources from nature, provide food to consumers, and return the resources to nature, CJ CheilJedang has implement its Sustainable Environmental Management Project. Through this project, we will identify sustainable environmental strategies·goals and implementation systems and deliberate on them at meetings of the Coporate Sustainability Committee. | ||||||||||||

| Strategy | In the short term, we will establish and manage reduction targets for GHG emissions and energy consumption to eliminate financial impacts caused by the overuse of GHG emissions allocations. In addition, we are implementing a sustainable environmental management project to establish mid- to long-term environmental management strategies and implementation systems. We plan to increase the use of renewable energy and introduce bio-energy as well as additional solar energy. | We will publish the environmental(climate change) policies and strategies as well as the mid-to long-term goals approved by the Board of Directors in a special report on our climate change response at the end of 2021. By developing a prototype for a climate change risk cost calculation model, CJ CheilJedang will quantitatively and qualitatively identify risks and opportunities in consideration of climate change scenarios and reflect them in our future management strategies within the next three years. | ||||||||||||

| Risk Management |

To alleviate business and environmental impacts caused by climate change and respond preemptively, we monitor GHG emissions and energy consumption. CJ CheilJedang has defined and proactively manages domestic GHG emissions, storms and floods as major risk factors. We have also expanded our scope of risk management to include the GHG emissions risks of our suppliers. | We will quantitatively and qualitatively identify risks and opportunities with consideration for different climate change scenarios and establish integrated management with a company- wide risk management process within the next three years. | ||||||||||||

| Indicators and Reduction Targets |

To report GHG emissions under the Act on the Allocation and Trading of

Greenhouse-Gas Emissions Permits (Emissions Trading Act), we set a goal of reducing

emissions by 33% compared to BAU by 2030 based on the 2030 National GHG Emissions

Reduction Roadmap and past data (GHG emissions, emissions intensity, and production

volume).

|

We plan to re-establish our mid- to long-term goals(to be achieved by 2030 and 2050) to contribute to achieving the targets of the Paris Agreement and minimize environmental impacts through the Sustainable Environment Management Project. In addition, we will measure scope 3 emissions, in both the upstream and downstream sectors, and flesh out detailed strategies to achieve mid- to long- term goals within the next three years. |